Definition of a Factory Automation System

A factory automation system is a system of implementing technology to operate a manufacturing process with the ultimate aim of increasing productivity and being more cost-efficient. By installing a factory automation system for certain industries, we can reduce human involvement with incorporation of technology.

Types of Factory Automation Systems

There are four types of factory automation systems that are different in terms of degree automation, human involvement, and efficiency to handle the automation systems:

i) Manual or Minimal Automation

This type of factory automation system requires human involvement as the automation system only offers a minimal level of automation. The whole manufacturing process is done manually. Examples of processes that require manual or minimal automation are inspection for quality of products, and manual product assembly. If you would like to install and operate a manual or minimal automation system, you need to train people with proper training and professional guidance. At the same time, you need to introduce them to the safety guidance to create a harmless and less risky work environment.

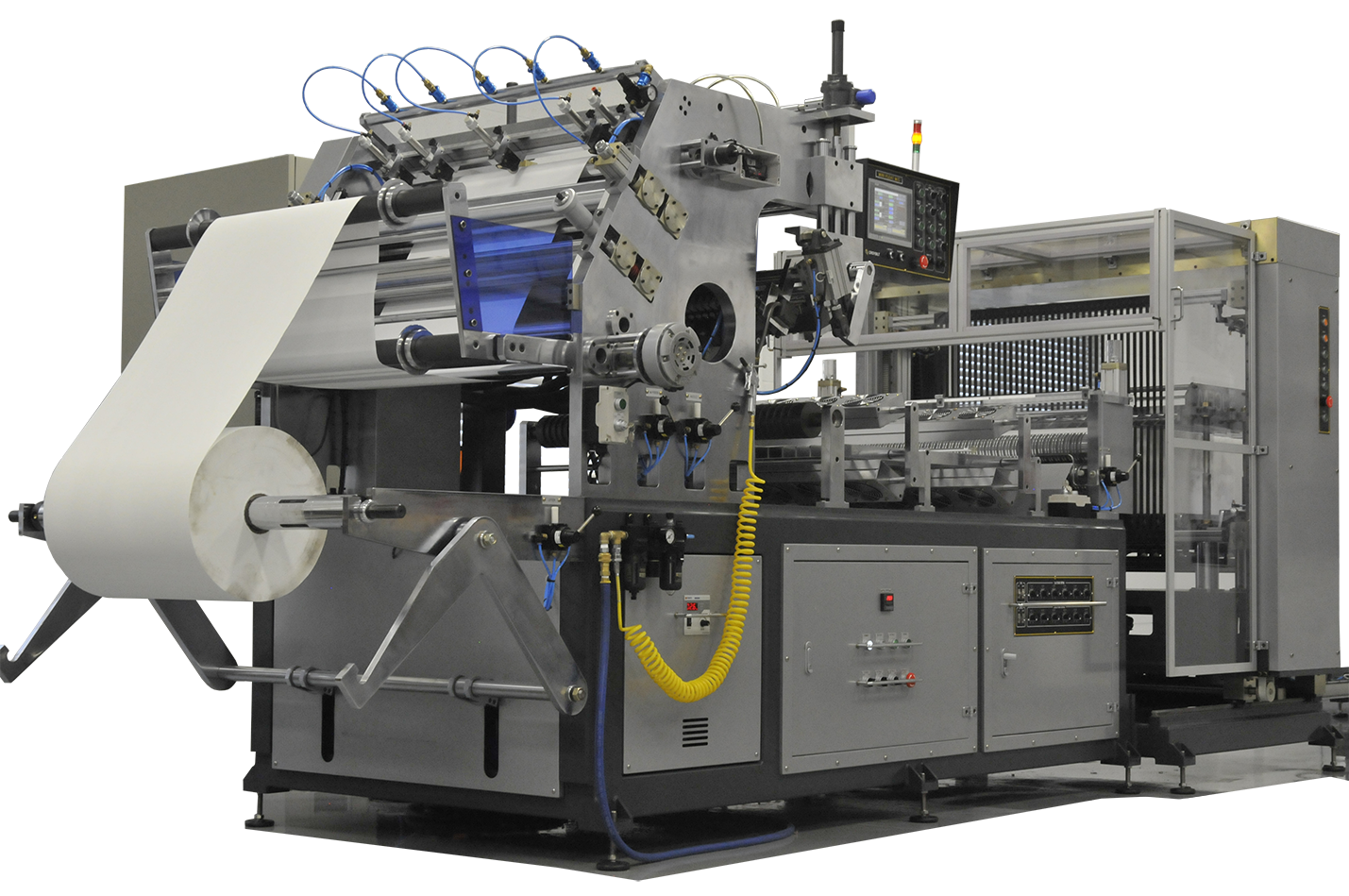

ii) Single Automated Machines

The single automated machines are designated for repetitive processes at the workplace. Examples of repetitive processes are cutting packages and inspecting. The parts that you would like to pass on the single automated machines may be manually inserted and positioned into those machines.

iii) Automated Production Lines

According to NGS Engineering (2021), automated production lines usually combine material transfer on a conveyor system with a series of dedicated workstations, each designed to fulfil a specific purpose in the cycle of production. The chronology of work is fully defined and the level of operator involvement depends on the amount of automation. Supervision, monitoring, adjustment and maintenance of equipment are the only things that are required to run a fully automated production line.

iv) Fully Automated (End-to-end Automated System)

The fully automated (end-to-end automated system) is the highest level of automation. This type of factory automation system can operate for 24 hours a day and the whole year without any limitation or requirement to handle it. You can leave a fully automated system without supervision of humans at the workplace and you do not need to conduct regular training for your employees to help run this machine.

—————————————————————————————————————————

Xyreon’s Factory Automation System – Trusted and A more seamless Production

Xyreon is a trusted supplier of industrial PC and automation systems that offers several factory automation system for you and your industry!

Why Should You Install Xyreon’s Factory Automation System?

By installing Xyreon’s Factory Automation System, it can be beneficial for you, your employees and even to the production. Here are the benefits of installing Xyreon’s factory automation system:

- Improvement in productivity.

- Create a safer working environment.

- Increase quality in production.

- Reduce plans that are not strategic. By using Xyreon’s factory automation system, you could calculate the exact amount of materials that you really need for the manufacturing process and avoid waste.