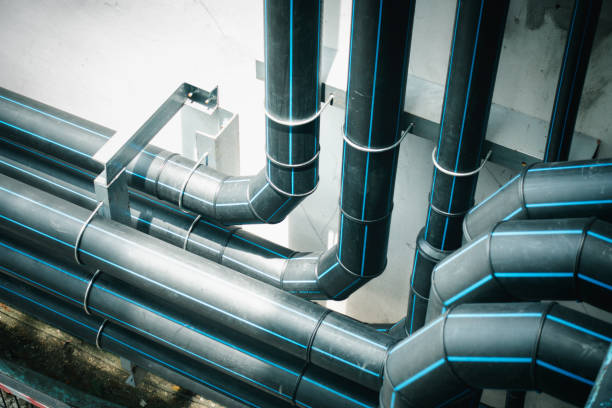

When it comes to reliable and long-lasting piping solutions in harsh Malaysian conditions, HDPE pipe Malaysia systems stand out for their durability, flexibility, and corrosion resistance. Whether for municipal water systems, agriculture, or industrial use, HDPE (High-Density Polyethylene) pipes offer a compelling alternative to traditional materials like PVC or steel.

What is HDPE Pipe, and Why Is It Ideal for Malaysia?

HDPE pipe is made from thermoplastic material known for its high strength-to-density ratio. It is especially suitable for Malaysia’s tropical climate, where high humidity and aggressive soil conditions can degrade conventional piping systems. HDPE pipe’s resilience to UV, chemicals, and extreme temperatures makes it a preferred choice for long-term infrastructure investments.

Key Advantages of HDPE Pipes in Malaysia

In about 40 words:

HDPE pipes are lightweight, corrosion-resistant, and flexible, making them ideal for Malaysia’s challenging environmental and infrastructural needs. Their long service life and low maintenance costs provide excellent ROI across both public and private sector applications.

Some key benefits include:

- Corrosion & Chemical Resistance: Ideal for acidic soils and industrial fluid transport.

- Leak-Free Joints: Heat-fusion joints reduce leakage and water loss.

- High Impact Strength: Perfect for installations in unstable terrain or flood-prone zones.

- Cost-Effective Over Time: Reduced repair costs and long service life.

Where is HDPE Pipe Commonly Used in Malaysia?

Across Malaysia, HDPE pipes are frequently used in:

- Water supply distribution systems

- Agricultural irrigation

- Sewage and drainage systems

- Cable conduit protection

- Gas pipelines

- Firefighting systems in high-rise buildings

Due to their adaptability, HDPE piping systems are popular in both urban and rural infrastructure projects.

HDPE vs. PVC Pipes: Which Is Better?

While both PVC and HDPE pipes serve essential functions, HDPE pipes are generally more flexible and impact-resistant. Unlike PVC, HDPE can expand and contract under stress, reducing the risk of cracks. Additionally, HDPE joints are heat-fused, creating a more secure seal compared to solvent-welded PVC joints—this is especially valuable in seismic zones or heavy rainfall regions in Malaysia.

Choosing the Right HDPE Pipe in Malaysia

When selecting an HDPE pipe system, consider:

- Pipe Diameter: Depending on flow requirements and installation environment.

- Pressure Rating (PN): Ensure it matches the intended application (e.g., PN10, PN16).

- Standards Compliance: Look for products certified under MS 1058, ISO 4427, or equivalent.

- Supplier Reputation: Always choose a supplier with proven product quality and after-sales support.

One of the most reliable suppliers in the region is HDPE pipe Malaysia, offering a wide range of certified piping systems tailored for Malaysian infrastructure needs.

Conclusion: Why HDPE Pipe is the Smart Choice for Malaysia

HDPE pipe Malaysia solutions provide unmatched longevity, flexibility, and resilience under local environmental stressors. Their low-maintenance and high-performance profile make them a wise investment for any infrastructure or utility project.

Ready to upgrade your piping system? Explore top-rated HDPE pipe solutions today and future-proof your operations for decades to come.